- Home

- High Durability

DURABILITY PROVEN BY TESTS AND CERTIFICATES

HIGH DURABILITY OF THE SOLROOF SYSTEM

At SOLROOF, we’ve developed a solution that combines tempered glass with extremely durable XCarb® recycled and renewably produced steel from ArcelorMittal. As a result, our panels feature exceptional resistance to perforation and mechanical damage, maintaining their aesthetic appearance and full functionality for many years. The durability of the construction is confirmed by numerous tests and certificates, as well as warranties extending up to 60 years with the XTREME [XT] coating.

XCarb® recycled and renewably produced od ArcelorMittal

Steel – the foundation of reliability

Glass photovoltaic panels do not provide the same level of protection as steel, which forms the foundation of our solution. Steel is resistant to mechanical damage and easy to maintain, meaning that hail or strong impacts do not threaten the roof’s tightness or durability. That is why at SOLROOF we integrate tempered glass with steel – to create a system that protects your home while producing clean energy at the same time.

Prestigious VDE Certification for SOLROOF

The panels of our SOLROOF system have passed rigorous tests at the Fraunhofer Institute, and our production line has also received certification.

What Does this Mean for SOLROOF Customers?

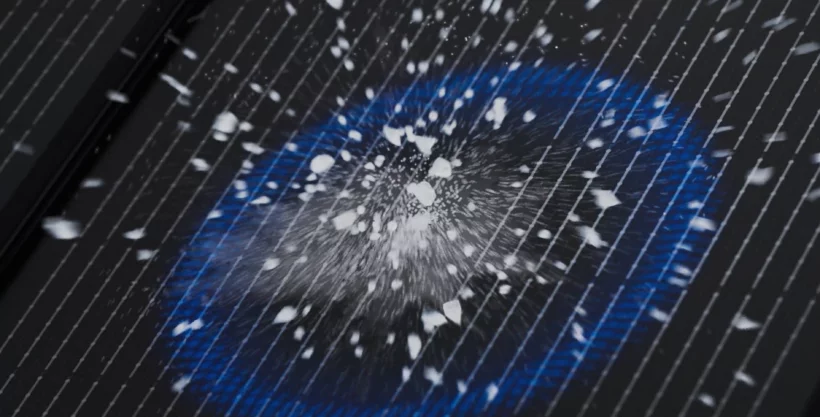

Hail resistance – The SOLROOF roof effectively protects your home from hail! In a specialized test, the modules were subjected to impacts from ice balls up to 25 mm in diameter, fired at a speed of 23 m/s (83 km/h).

Moisture and condensation resistance – SOLROOF passed a crucial endurance test, confirming resistance to prolonged exposure to high temperature and humidity: 1000 hours at 85°C with 85% relative humidity.

Overheating resistance – SOLROOF passed the durability test for hot spots, which are local overheating and self-ignition points that can affect the module’s lifespan and safety.

Extreme temperature resistance – SOLROOF panels successfully completed 200 test cycles in extreme temperature conditions from -40°C to 85°C, in accordance with IEC 61215 standard.

Ice resistance – The panels underwent a demanding test involving 10 cycles of varying temperatures from -40°C to 85°C at high humidity (85%).

The panel tests were conducted by the renowned Fraunhofer Institute for Solar Energy Systems ISE – part of Fraunhofer-Gesellschaft, Europe’s largest independent research institution. The organization specializes in advanced testing of modern technologies, with particular focus on the photovoltaic sector. Fraunhofer-Gesellschaft comprises 66 German research institutes, establishing itself as an authority in energy innovation.

Fire Safety

SOLROOF holds the BROOF (t4) certificate, confirming the highest class of fire resistance for roofs in Europe. Independent tests have shown that the system does not ignite, prevents fire penetration into the building, and maintains maximum protection for over 60 minutes, surpassing standard BIPV solutions and traditional photovoltaics.

Self-ignition is most Commonly Caused by:

❌ Incorrectly routed cables – including routing cables where they are exposed to friction or crushing, or improper installation (loose, without proper fastening, or without additional UV protection).

❌ Too many parallel connections with cables of insufficient cross-sections – this design flaw can lead to cable overload and ultimately ignition.

❌ Lack of grounding – equipotential bonding improves the safety of photovoltaic installations in terms of potential surges, shock risks, and electrical discharges. Unfortunately, many installers completely overlook this aspect.

❌ Mounting components on flammable materials – both photovoltaic panels and devices such as inverters can reach very high temperatures during operation.

Tests Have Proven that the SOLROOF Roof Does not Melt and Effectively Protects against Fire.

✔️ SOLROOF panels do not self-ignite or melt from high temperatures.

✔️ Fire does not spread across their surface.

✔️ Bypass diodes minimize hot spot formation and thus prevent self-ignition.

✔️ We use SolarEdge optimizers that control panel operation and prevent voltage spikes while allowing panel monitoring. They are mounted on ventilated rails using the best certified connectors available on the market.

Durability at speeds of up to 41 m/s

Hail resistance

FIT VOLT panels have passed hail impact tests, meeting European requirements not only of the SIA 261 standard — HW4 class, but also the IEC 61215-2 standard.

What does this mean in practice?

To comply with the IEC 61215-2 standard, a product must successfully withstand hail impact tests using hailstones traveling at a minimum speed of 30.7 m/s, with a diameter of 45 mm and a mass of 42.9 g. SOLROOF panels successfully maintain durability at speeds of up to 41 m/s!

All of this is made possible by integrating tempered glass with steel – a highly durable and easy-to-maintain material – resulting in exceptional resistance to hail impact.

XTREME [XT] – Extreme Durability

The XCarb® recycled and renewably produced steel used in SOLROOF can be coated with our most durable XTREME [XT] coating.

This technology sets a new standard in weather resistance and protection while supporting sustainable production.

🟡 Highest corrosion resistance RC5+ – perfect for coastal and industrial zones

🟡 70 microns of multilayer protection against rain, sun, and extreme temperatures

🟡 Deep black XT33 – modern shade matched to contemporary architecture

🟡 Resistance to fading and loss of gloss even with intense UV exposure

🟡 60-year warranty under standard conditions and 40 years in demanding coastal zones

GET INSPIRED BY OUR PROJECTS

SOLROOF System Implementation – Application in a Modern Building

245 m²

8,4 kWp

52 m²

Modern Architecture with SOLROOF System – Aesthetics and Functionality

260 m²

16,1 kWp

99 m²

SOLROOF System Installation on a Gable Roof

391 m²

9,975 kWp

61 m²

Modular House with Integrated SOLROOF System

79 m²

2,97 kWp

19 m²

SOLROOF Implementation – Log House with Photovoltaic Roof

305 m²

15,05 kWp

92 m²

SOLROOF System Implementation – Application in a Modern Building

245 m²

8,4 kWp

52 m²

DO YOU HAVE ADDITIONAL QUESTIONS

ABOUT THE SOLROOF SYSTEM?

Our hotline is available from 8:00 AM to 4:00 PM Monday to Friday.

We encourage you to fill out our contact form.

© Copyright 2026